QUALITY COMES FIRST

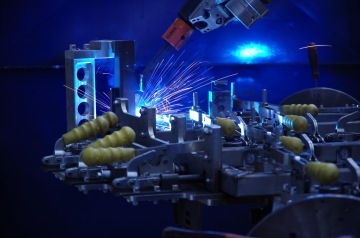

KASPER KOVO s.r.o. has created great conditions for the welding of all common materials. All welding operations are performed with professional welding aggregates and systemic welding benches.

In manufacturing, there are separated welding stations for welding of standard materials and stainless steel, which are divided according to individual production programs to ensure that the specific products are processed by stable staff.

The welding of pressure vessels is a specific area where the production efficiency is ensured by the use of semi-automatic machines and positioning equipment. Welding of strength joints in pressure vessels of large sizes up to 4m is carried out using an ESAB welding robot

WELDING METHODS

-

MIG,MAG

-

TIG-AC/DC

-

MMA – ARC welding

-

Stud welding

-

Spot welding

-

Semi-automatic and mechanized welding of vessels

-

Sub-arc welding of pressure vessels up to the diameter of 4m

-

Welding robots Cloos and Migatronic

WELDING MATERIAL

-

Class 11 steel

-

Class 17 steel

-

Aluminium (AL mg 3)

ARE YOU INTERESTED IN

THIS PART OF PRODUCTION?

For any questions or interest in cooperation, do not hesitate to send us a non-binding request.

We will be happy to help you with the production of products.