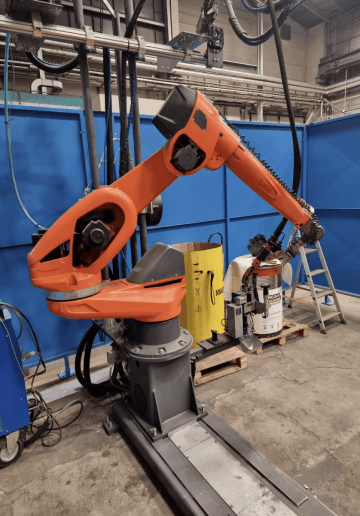

Cloos QRC-350-E

The QIROX QRC-350-E is a six-axis robot with an articulated arm, a working area of 3,500 mm in length, a diameter of 2,000 mm and an extended reach with a seventh robot axis. The mechanics allow versatile use and the execution of many different processes, the rotary positioner ensures perfect positioning and consistent welding even in complex structures. The robotic workplace is adapted for welding of stainless materials such as stainless steel or aluminium alloys by the MIG/MAG method. MAG technology ensures high productivity and the ability to handle thicker materials. The quality of welds and the efficiency of the whole process are enhanced by a two-axis positioner, which ensures optimal adjustment of all parts of the welding vessel. The robot is designed to achieve repeatable accuracy.

Cloos QRC-410-E

The QIROX QRC-410-E is a six-axis robot with a classic wrist, a working area of 4,100 mm and a longer reach thanks to the seventh robotic axis. The mechanics allow versatile use and the execution of many different processes, the rotary positioner ensures perfect positioning and consistent welding even in complex structures. The robot handles all MIG/MAG welding processes, welding of classic carbon steels. MAG technology ensures high productivity and the ability to handle thicker materials, such as pressure vessels. The quality of welds and the efficiency of the whole process are enhanced by a rotary positioner, which ensures optimal adjustment of all parts of the welding vessel. The robot is designed to achieve repeatable accuracy.

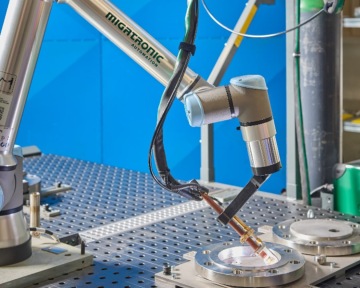

ROBOT CoWelderTM

The collaborative robot CoWelderTM is equipped with TIG technology (welding of stainless steel, aluminium alloys), known for its precision and quality and its suitability for fine welding, where attention to detail and aesthetics is emphasised. It is designed to work safely with human operators, allowing easy programming and flexibility in handling different components. The robotic arm has a load capacity of 12.5 kg, a reach of 1,300 mm, a rotation speed of up to 180 deg/s and repeatability with a tolerance of ±0.1 mm.

Trumpf TruBend Cell 7000

TruBend Cell 7000 is a fully automated system for tilt bending of sheet metal with bend lengths up to 0.5 m. The angular robot ensures precise positioning, the ACB automatic angle measurement and correction system for bending sheet metal guarantees precise results from the first piece, and the integrated tool changer allows quick adaptation to different operations. The machine is designed to handle even complex parts quickly, in an energy-efficient way and with minimal error. The robotic cell is equipped with automatic tool change according to the selected program.

ARE YOU INTERESTED IN

THIS PART OF PRODUCTION?

If you have any questions or are interested in cooperation, please do not hesitate to send us a non-binding enquiry.

We will be happy to help you with the production of products.